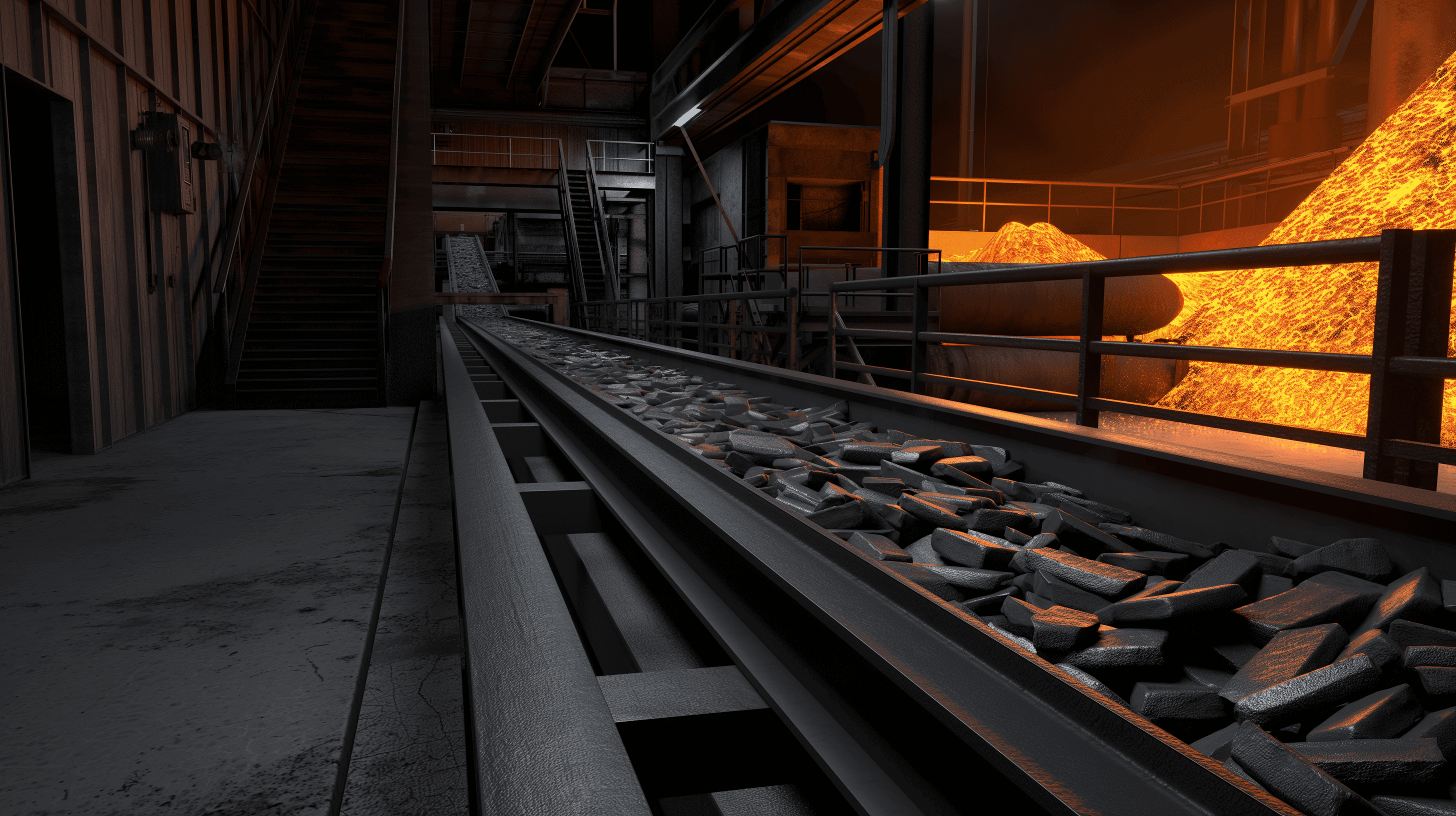

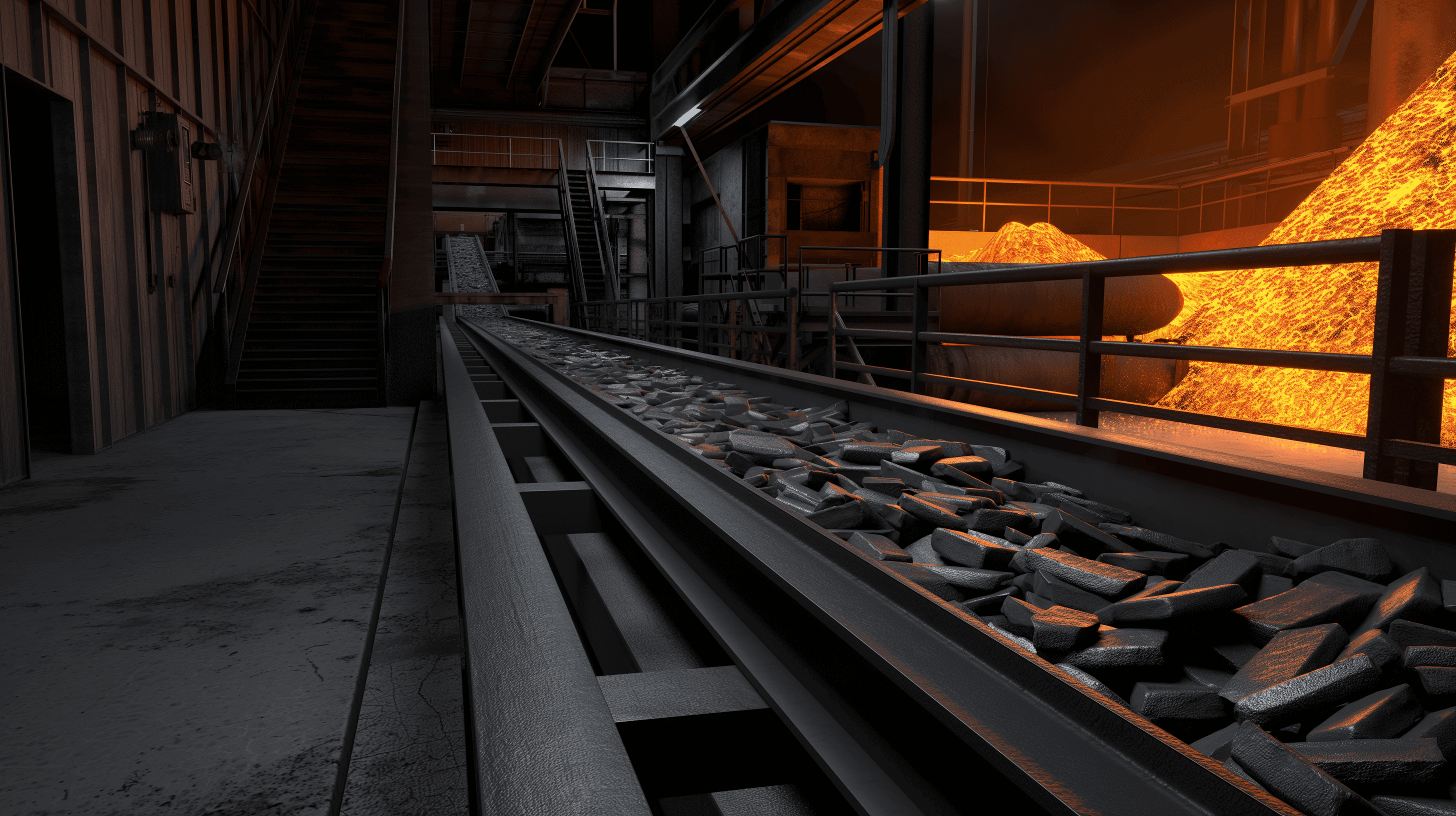

Sorting conveyors

Reduce labor costs and increase throughput with the world’s best sortation conveyor systems, American-made and American engineered.

Reduce labor costs and increase throughput with the world’s best sortation conveyor systems, American-made and American engineered.

Our conveyors deliver exceptional durability, strength, and longevity under punishing conditions.

We design and build each conveyor for ease of maintenance, longevity, and performance.

We can build a custom conveyor solution to your exact specifications.

We offer a broad range of customization options for our sorting conveyors.

Need additional customization? Our engineering team can build an innovative solution to your specs.

Explore a wide range of applications where our wash plant conveyors excel:

Our conveyors withstand the rugged demands of any application.

If you need a conveyor system tailored for your sorting application, let's discuss your requirements.

Clear guidelines ensure wash plant sorting systems are designed, operated, and maintained with efficiency and safety in mind. By standardizing processes and documentation, teams can improve reliability, reduce downtime, and support accurate installation and operation across various plant layouts.

Here are some of the many conveyor projects we’ve done for some amazing customers across the US.

Fluent conveyors manufactures conveyor solutions for applications across recycling, waste management, logistics, and other industries. Choose your conveyor below to get started.

Copyright © 2025 Fluent Conveyors, LLC. All right reserved

Fluent Conveyors logo is a registered trademarks of Fluent Conveyors, LLC. Serial Number 97664258 Registered on Dec. 12, 2023